Abstract

Within the realm of high-end horology collection and maintenance, automatic watch winders play a pivotal role. For collectors possessing multiple automatic mechanical timepieces, these devices serve not only as auxiliary tools for time management but also as critical instruments for maintaining optimal movement lubrication and ensuring the continuous operation of complex complications. This article provides a professional analysis of selection criteria and practical applications, examined through the lenses of mechanical principles, technical specifications, market categorization, and maintenance protocols.

I. Mechanical Necessity Analysis for Automatic Winding Devices

1. Continuity Assurance for Complications

Automatic mechanical watches rely on kinetic energy input from the wearer. For timepieces equipped with high-precision complications—such as Perpetual Calendars, Annual Calendars, or Moon Phases—continuous operation of the mechanical structure is essential. Once power is depleted and the watch stops, the subsequent calibration process for complex calendars is not only exceptionally challenging but also risks damaging delicate micro-mechanical components through frequent manual adjustments.

2. Dynamic Maintenance of Lubrication Systems

Watch movements contain various types of micro-lubricants. Prolonged periods of inactivity can cause these lubricants to distribute unevenly due to gravity, or even lead to coagulation and sedimentation in certain environments. By simulating natural motion, a watch winder ensures that internal components remain in a state of dynamic lubrication, effectively extending the service life of the mechanical structure and lengthening maintenance intervals.

3. Display Aesthetics and Asset Protection

For high-value horological assets, professional winding devices often utilize premium materials such as high-density fiberboard (HDF), piano lacquer, or carbon fiber. These materials provide physical protection while complementing the display requirements of high-end assets.

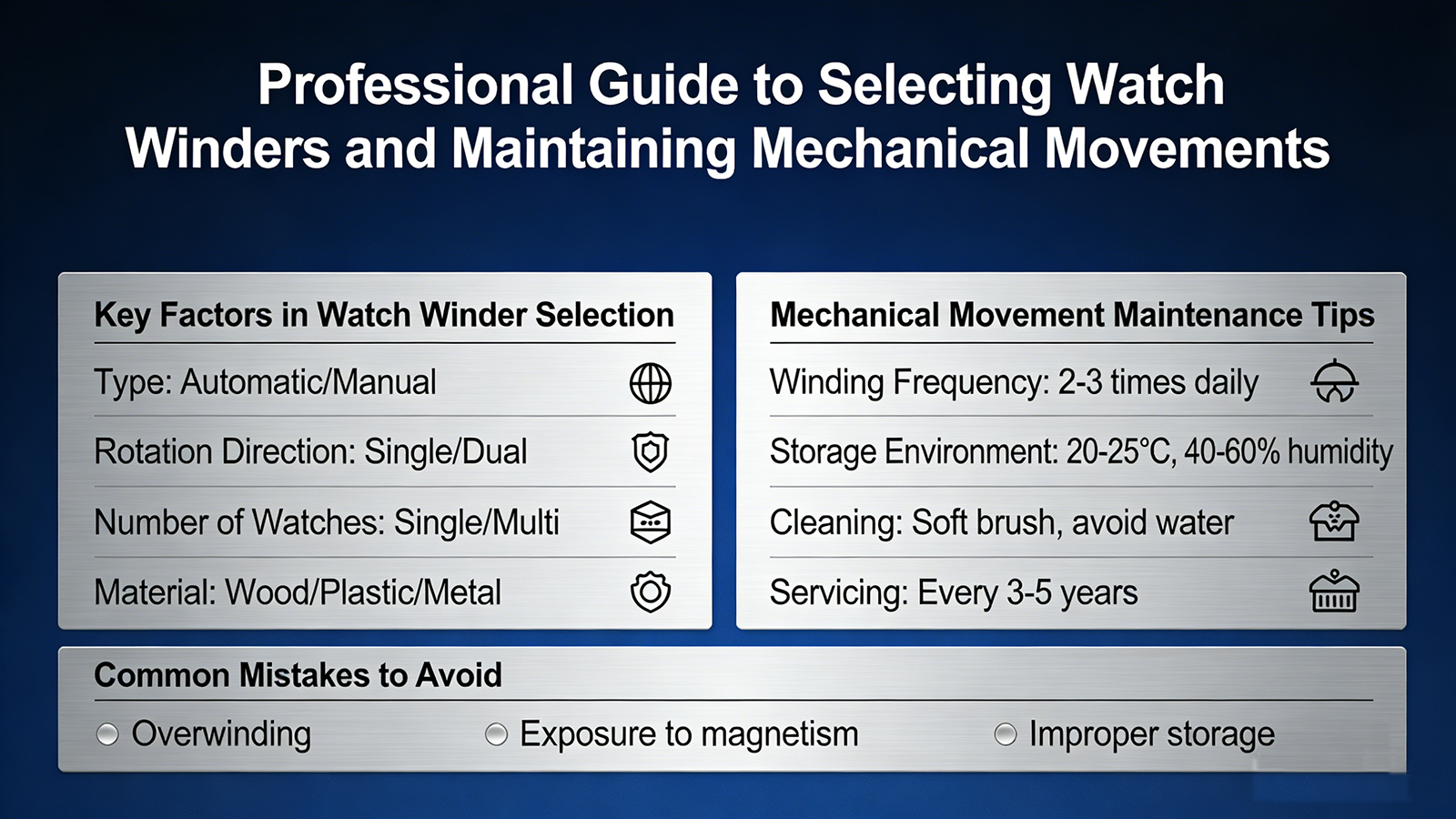

II. Core Selection Indicators and Technical Principles

When evaluating automatic winding devices, the following technical parameters must be strictly scrutinized to prevent potential damage caused by equipment defects:

1. Magnetic Shielding Effectiveness (Critical Safety Threshold)

The electromagnetic fields generated by electric motors pose a significant threat to the hairsprings of mechanical watches. Magnetization of the hairspring leads to erratic oscillation frequencies and timing inaccuracies.

- Technical Requirements: Premium equipment should utilize magnetic shielding encapsulation, such as Permalloy shielding covers.

- Physical Considerations: Manufacturers must ensure sufficient physical displacement between the motor spindle and the watch cuff to keep residual magnetic flux density below international safety standards.

2. Precision Control of Turns Per Day (TPD)

TPD (Turns Per Day) is the core logical indicator for measuring device performance.

- Risk Mitigation: Insufficient power input leads to chronometric errors, while excessive power load may cause the slipping spring (overwind protection) to engage too frequently. Although a safety feature, constant slipping can accelerate wear on the escapement and winding mechanism.

- Industry Standards: Qualified devices must offer multi-gradient TPD adjustments (e.g., 650, 750, 850, 1000 TPD) to accommodate the specific torque requirements of various calibers.

3. Winding Direction Compatibility Logic

Different calibers utilize various automatic winding architectures (such as unidirectional or bidirectional ratchets) and have specific directional requirements:

- Clockwise/Counter-clockwise (Unidirectional): Certain precision movements only achieve energy charging when rotated in a specific direction.

- Bidirectional: The optimized path commonly utilized by the majority of modern mainstream movements.

- Functional Requirements: Ensure the device features independent directional control modes to guarantee compatibility across different brands.

4. Quality Stability of the Power Assembly

- Motor Selection: The industry generally regards Japanese Mabuchi motors as the benchmark for silence and durability.

- Acoustic Standards: Operational noise levels should be maintained below 20 decibels to comply with acoustic standards for residential or office environments.

III. Market Tiering and Value Dimension Analysis

The following table categorizes current mainstream market products based on technical specifications and material craftsmanship:

| Dimension | Entry-Level Devices | Professional-Grade Devices | Luxury Collection Systems |

|---|---|---|---|

| Drive Core | Standard DC Motor | High-Efficiency Silent Motor | Swiss-Made / Micro-Brushless Servo Motor |

| Magnetic Shielding | Basic Physical Distance Isolation | Multi-Layer Metal Shielding Process | Patented Zero-Magnetism Technology |

| Logical Control | Fixed Cycle Programs | Independent TPD & Directional Adjustments | Digital Control / App-Based Cloud Sync |

| Craftsmanship | Polymer or Synthetic Materials | Premium Wood / Microfiber Leather | Advanced Composites / Security-Grade Locks |

| Design Life | 12 – 24 Months | 60 – 120 Months | Designed for Lifetime Maintenance |

| Target Calibers | Basic Entry-Level Movements | Mainstream & High-End Automatic Calibers | Complications / High-Value Collectibles |

IV. Industry Frequently Asked Questions (FAQ)

Q1: Does the long-term use of an automatic winder cause excessive mechanical wear?

A: Based on mechanical dynamics analysis, provided that TPD and rotation cycles are scientifically configured, the mechanical load generated by the device is significantly lower than the kinetic impact of daily wear. On the contrary, maintaining regular movement is beneficial for preserving the physical properties of the lubrication system.

Q2: How can I determine the recommended settings for a specific caliber?

A: It is recommended to consult the Orbita Database or the official technical manual for the movement. Generally, Rolex suggests a setting of 650 TPD (Bidirectional), while Omega Co-Axial movements are typically set between 650-800 TPD (Bidirectional).

Q3: Where is the technical premium reflected in high-priced devices?

A: The premium primarily stems from power assemblies with extremely low failure rates, patented “Return-to-Home” functions (ensuring the watch stops in a vertical, 12 o’clock position), stringent magnetic shielding standards, and high-end artisanal assembly.

V. Selection Decision and Conclusion

When making a selection, the principle of “Caliber Compatibility First” should be upheld. For collectors of high-value timepieces or those with complications like perpetual calendars, priority should be given to professional-grade equipment or higher, featuring precise TPD adjustment and robust magnetic shielding. Investing in a high-quality winding device is not only a guarantee of chronometric precision but also a commitment to maintaining the long-term value of a mechanical asset.